Manufacturer Supply Tungsten Carbide Wire Drawing Dies Copper Wire Drawing Dies

1.about Us

Zhuzhou Good Cemented Carbide Co.,Ltd. established in Zhuzhou City, Hunan Province, the largest tungsten carbide producing area in China and now our office moved to Changsha city, capital of Hunan province. We own a factory specialized in cemented carbide and related tools, we also do many other OEM products as request from customers. As a professional manufacturer, we are equipped with advanced equipments and specialized persons, especially have rich experience in making customized products. Over 10 years, we have been committing to "High Quality, Best Price, Sincere Service" as soul of our factory.

Our factory have a whole set of machines, including sieve shaker, press machine, sintering furnace, dryer, grinder, lathe, milling machine, cnc wire-cut machine, radial drilling machine, spark erosion drilling machine, etc. We also gathered the professional staff members in the area of designing, producing and sales and our workers are well trained and experienced.

Our main products includes: tungsten carbide inserts, cast tungsten carbide powder, geoglogical and mining tools, throw cast tungsten carbide ingots, tungsten carbide welding rods, carbide burrs, end mills and drill bits, crushing of carbide hammer and anvil, tungsten carbide glass and tile cutting wheels, precision casting parts, tungsten carbide balls, strips and plates, tungsten carbide roll rings, disc cutters and blades, brazed tips, drawing dies, blasting nozzles, cold forging dies, punching dies, new non-magnetic carbide tools, carbide wear parts, pure tungsten, etc. We can also manufacture various type of precision tools, non-standard and deep-processing products according to drawings and so on.

2.about our Service

1) 100% quality guarantee (ISO9001)

2) Various size for selection

3) Professional technical support

4) OEM & ODM are welcomed

5) Small order is acceptable

6) Factory service with competitive service in the market

7) Delivery in time

8) Flexible payment terms(L/C,T/T,western union, Paypal, etc.)

9) Best after-sale service

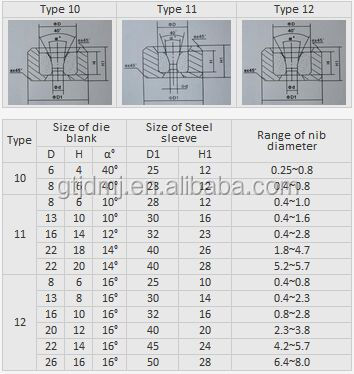

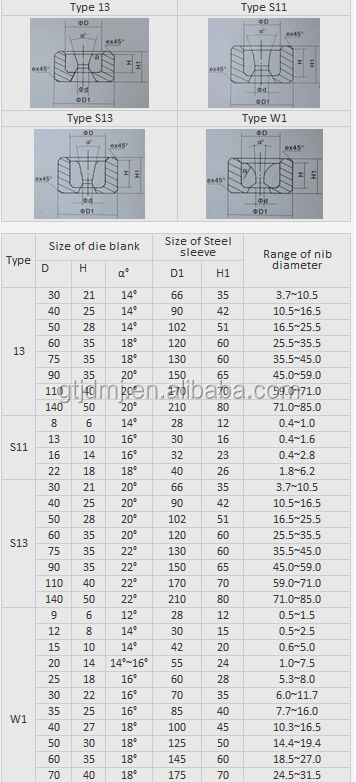

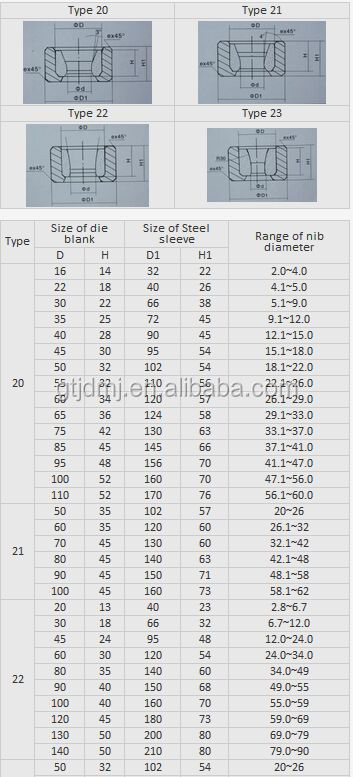

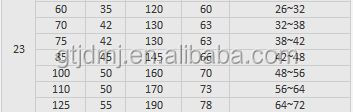

3.tungsten carbide wire drawing dies specification

1).Introduction

The tungsten carbide wire drawing dies are made by 100% virgin raw material. The tungsten carbide has low impurity content so the wire drawing dies won’t crack easily. With HIP (Hot Isostatic Press) process to ensure the stable microstructure, the service life time of wire drawing dies is longer. So die change is less and it can improve the working & production efficiency.

The wire drawing dies have wide application and they can be used for drawing copper, aluminum, steel, spiral wires, ferrous and nonferrous wires, rods and tubes, etc.

2).Size

3).Grades

|

Equivalent grade

|

ISO grade

|

WC%

|

Co%

|

Hardness (HRA±0.5)

|

Density (g/cm3±0.1)

|

TRS

|

Characteristics and Application

|

|

Mps

|

|

Min

|

|

YG6X

|

K01

|

94

|

6

|

93

|

14.85

|

2700

|

The fine grain size, suitable for processing of non-ferrous metal finishing and woodworking cutting tools.

|

|

YG10X

|

K20

|

90

|

10

|

92

|

14.45

|

3400

|

suitable for all kinds of milling cutter and hole machining tool.

|

|

YG13X

|

K20

|

86.5

|

13.5

|

90.5

|

14

|

3500

|

excellent abrasion resistance and toughness, suitable for carpenter's tools.

|

|

YG6A

|

K10

|

94

|

6

|

92

|

14.95

|

2450

|

suitable for wire drawing die and woodworking cutting tools.

|

|

YG6X

|

K10

|

94

|

6

|

91.5

|

14.95

|

2500

|

applies to non-ferrous metal cutting.

|

|

YG6

|

K20

|

94

|

6

|

91

|

14.95

|

2600

|

Used for rough machining of non-ferrous metals.

|

|

YG8

|

K30

|

92

|

8

|

90

|

14.7

|

2700

|

suitable for wire drawing die, drawing die.

|

|

YG11

|

K40

|

89

|

11

|

88.5

|

14.45

|

2900

|

suitable for wearing parts and mining tools.

|

|

YG12

|

K40

|

88

|

12

|

89

|

14.4

|

3000

|

suitable for rough machining of non-ferrous metals.

|

|

YG13

|

K40

|

87

|

13

|

88.5

|

14.2

|

3100

|

suitable for wear resistance and resistance to stamping parts

|

Note:The size and grade can be customized as requirements.Welcome OEM&ODM.

4. tungsten carbide wire drawing dies Pictures